With the rise of ceramic coating in the automobile industry, many of the consumers ask about the difference between certain properties before buying a suitable product for themselves.

Among these coatings, 10H and 9H are often mentioned, but what do these labels mean and how do they differ?

First and foremost, let’s address a common misconception for those who believe there is no such thing as 10H in pencil hardness. While it is true that 10H is not an officially recognized value in the standard Pencil Hardness Test, several advanced manufacturers, such as Mitsubishi, have developed standard 10H hardness test pencils.

The Mitsubishi Hi-Uni 10H pencil, for instance, has been adopted by some international testing laboratories since 2019 as an additional benchmark for evaluating surface and coating hardness that exceeds the traditional 9H standard. This high-tech addition has provided valuable data for testing coatings with enhanced durability and scratch resistance.

So, while 10H is not part of the traditional scale, it is a legitimate tool used in modern testing for specialized applications.

Now, let’s delve into the fascinating world of ceramic coatings and find out what really makes a difference when arguing 9H versus 10H coatings. We will also look into what makes Nasiol’s product the best choice in paint protection for your vehicle.

What Do 10H and 9H Mean?

The “H” in the 9H and 10H represents hardness. This rating is based on the pencil hardness test, which is a standard test used in measuring the hardness of coatings. The test ranges from 6B, the softest, to 10H, the hardest.

A 9H rating would represent that the coating has the resistance to scratch from a 9H pencil, while the 10H rating represents more hardness.

What is the Pencil Hardness Test?

The pencil hardness test is one of the most common methods for studying the hardness and scratch resistance of coatings and materials. In some cases, it is referred to as the Wolff-Wilborn test. The most common test is performed using pencils with a range of hardness values from 6B being the softest to 10H being the hardest, in its possible capacity to scratch a certain coating.

These pencils are then used to conduct a test on the surface under a constant load at a specific angle to identify the grade required for the hardest pencil, which still does not expose a visible scratch.

Therefore, simple but effective, this method gives very important information in terms of durability and quality of coatings, which actually makes it a crucial tool in such industries as automotive, electronic, and construction.

The pencil hardness test is useful not only for quality work at factories and manufacturing but also for research and development work to ensure that coatings meet performance-based standards.

How does it test the limit of Ceramic Coatings?

The pencil hardness test is very affordable yet simple. This is the reason this is usually practiced the most in determining the hardness.

To obtain a rating, the pencil with the highest order (which is the 10H one) is selected. The pencil is moved scratching over the surface under a 45° angle with a a constant pressure. If the particular mark is made, then a softer pencil (9H and so on) is used until a pencil does not produce any scratch.

To ensure consistency, the test is repeated on similar surfaces.

Key Differences Between 9H and 10H Coatings

Hardness and Durability

9H Coatings: These are very hard coatings and due to this, they offer excellent scratch resistance. They give chemical and environmental contaminant protection, which will suit almost any vehicle and offer real performance compared with traditional waxes and sealants.

10H Coatings: This is the most robust, available, scratch-resistant, and durable coating—rated at 9H. Most of them are scratch resistant and hence very long-lasting, hence perfect for high-end vehicles and those in harsh conditions.

Composition

9H Coatings: Generally, high silicon dioxide concentration forms a hard protective shell on the vehicle’s surface.

10H Coatings: These will more likely be rich in SiO2 percent or other high-tech materials and combination of siloxane resins and catalyzers that provide them with hardness and protection abilities.

Application and Maintenance

9H Coatings: Much easier to apply, even easier to maintain, but highly in demand among DIYers and pros.

10H Coatings: With these, a little more careful application and maintenance may be required to bring out their best. Most of the time, they are applied by professionals to ensure the best performance due to the condensed content.

So is 10H Better than 9H?

To answer this generally, yes 10H is better than 9H, but it doesn’t mean that 9H is bad at all. Think of it as a software which is updated and has slightly better features, so you can perceive 10H ceramic coating as an updated version of 9H.

The pencil hardness test is just one among the several used to measure the effectiveness of ceramic coatings. Many other tests gauge a lot of different aspects such as abrasion resistance, impact durability, adhesion quality, oxidation resistance, gloss retention, resistance against sun rays and yellowing, drying times, and resistance against different chemicals—important benchmarks of the performance and value of any ceramic coating.

It is important to differentiate at this point that ceramic coatings differ in strengths and properties. For example, one could be good at resisting UV, but just bad at heat or abrasion resistance for another.

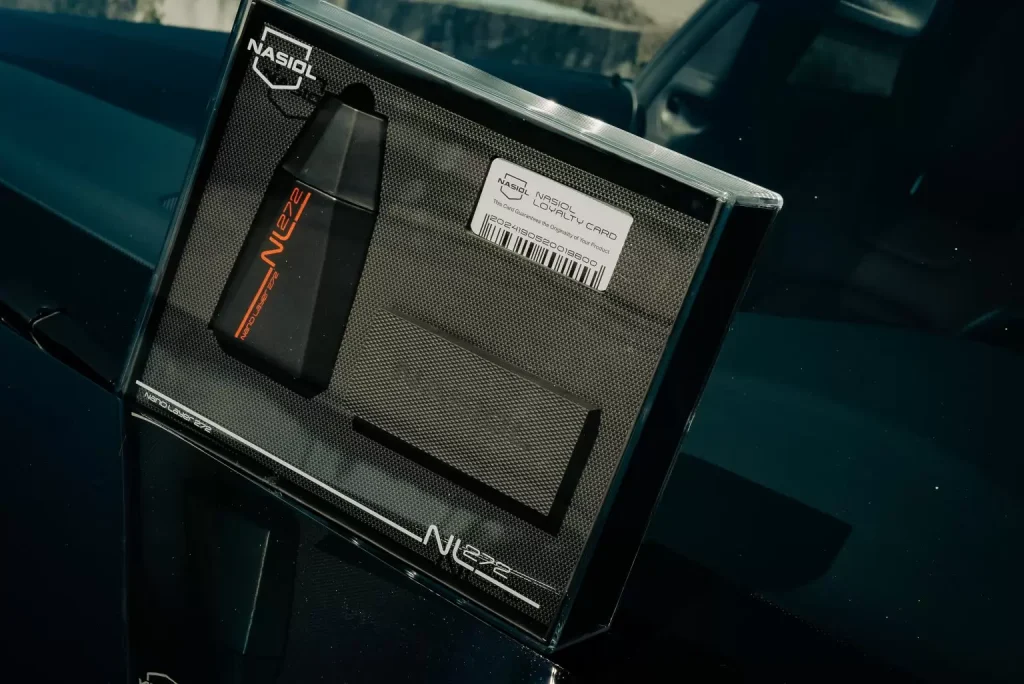

Lucky for you, Nasiol offers a diverse range of products which are one of the best you can find in the industry. Products like Nasiol ZR53 and Nasiol NL272 which offer 10H scratch resistant ultimate premium protection to your vehicle exterior, not only about the hardness level of coating but also combined protection against acids, strong base chemicals, UV rays.

Why Choose Nasiol?

Most coatings marketed as “ceramic coatings” are primarily composed of PDMS (Polydimethylsiloxanes), commonly known as silicone oils, blended with standard solvents like IPA (Isopropyl Alcohol) or toluene. These are not true nano coatings; instead, they are essentially synthetic liquid waxes with limited durability, typically lasting only a few months.

Nasiol Nano Coatings are not just simple two-component mixtures of polydimethylsiloxane and solvents. They are the result of advanced formulations designed to provide superior protection, durability, and performance far beyond conventional coatings

Nasiol is a creative, high-quality brand at the forefront of the ceramic coating industry. Here are some reasons why Nasiol’s 9H and 10H coatings make them the best choice for your vehicle:

High Technology: By infusing the formula with cutting-edge nanotechnology, class-leading protection and performance are guaranteed by Nasiol coatings.

Durable Protection: Both 9H and 10H coatings protect for a longer time; even years can go by with your vehicle looking new.

Application Ease: Nasiol has designed its products to be easily applied by professionals and DIYers.

Comprehensive range: Nasiol offers great variety for every use and taste—from everyday 9H coatings to coatings for maximum protection of 10H.

Final Words

The difference between a 9H and a 10H coating is a matter of importance for a person seeking to protect their vehicle. Though both offer exquisite protection characteristics, 10H coatings bring in extra durability and scratch resistance. With backing from advanced technology and a commitment to quality, Nasiol’s range of ceramic coatings ensures your vehicle receives the best care possible.

Be it a 9H or a 10H coating, Nasiol has the best-suited solution for your needs. Use Nasiol’s ceramic coatings today and experience the ultimate vehicle protection.